|

We have been doing different jobs for following sectors:

We help our constant partners with finding new markets. |

|

Servicing

Constant servicing

We provide consulting and help in technical problems on the basis of:

- our own specialized service staff

- clients’ personnel (and after a training agreed with the client)

- specialised equipment such as different appliances, laboratory equipment

- specialised lubrication system care software

- lubrication oil storage management on the basis of minimal lubrication means levels

- and spare parts storage management for hydraulic appliances (necessary stock)

- unification of filtration elements in the lubrication sets from the economic angle

- oil and greases by-products utilisation

- reliable analysis of servicing cost

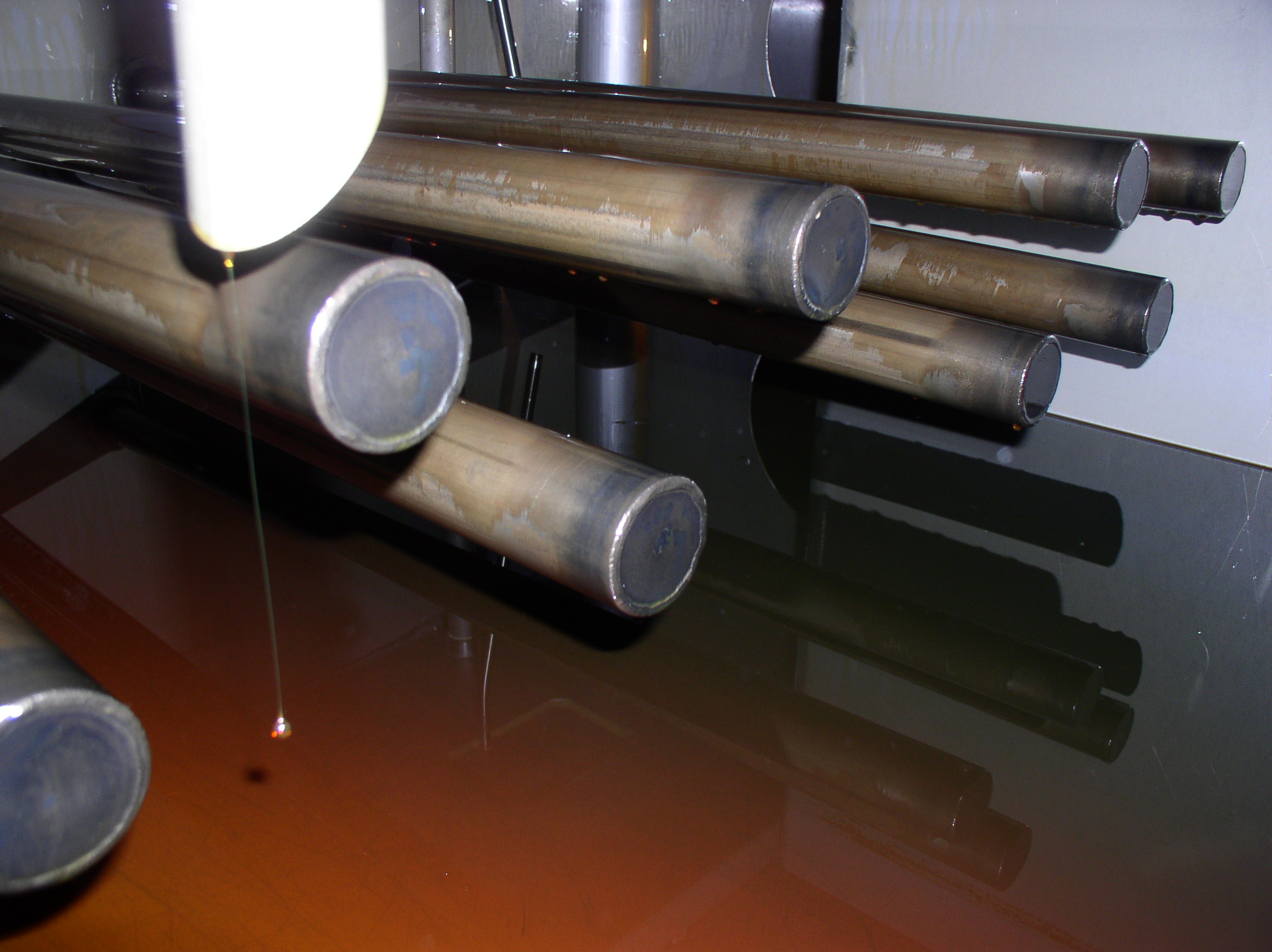

Hydraulic power pack under constant servicing.

Specialised paper industry servicing

1. Complex lubrication economy services through our own SOS servicing team.

2. One time services, such as:

- oil change in the lubrication sets

- lubrication of constant points

- specialised lubrication oil examinations

Specialised servicing for steam turbines

1. Cleaning and rinsing of steam turbines oil sets:

- Hydrodynamic oil pipelines cleaning under 50 MPa – 100 MPa (high pressures), with water as a cleaning factor

- Hydrodynamic cleaning of the main lubrication oil tank - doughing of tank walls

- Hydrodynamic cleaning of turbine oil radiator

- Eradication of water residues and drying of pipelines by compressed filtered air

- Rinsing by-passes of turbine oil system

- We ensure appropriate end result of oil system cleanliness according to PN-ISO 4406 12/09-13/10

2. Turbine oil circuits filtration systems modernisations

3. Steam turbines monitoring (examinations with commentaries and recommendations)

Servicing for steam turbines

Servicing activities for gas turbines’ oil circuits:

- Gas turbines oil change.

- Eradication of water residues and drying of pipelines by compressed filtered air.

- Rinsing by-passes of turbine oil system, up to achieving desired purity class of pipelines and oil.

- Turbine oil monitoring in the full scope of physic and chemical parameters, with graphic demonstration, showing trends of changes happening.

- Constant turbines oil systems servicing.

One-time Services

- Hydraulic circuits oil change

- Tanks cleaning

- Oil filtration up to the class, according to client's requirements or to DTR.

- Oil examinations

- Technical consulting and design

- Hydraulic aggregates construction

- Audits - hydraulic and lubrication circuits technical state appraisal, with the end report containing recommendations and guidance

- Specialised technical translations – Polish, Russian, French

Oil Examinations

We provide specialized oil examination services such as:

- turbine oil examinations

- full oil and service monitoring

- hydraulic oil examinations

- we provide complex oil monitoring, that ensures longer oils life and allows economies gear oil examinations

- full gear oils monitoring

- we do full monitoring of gear oils

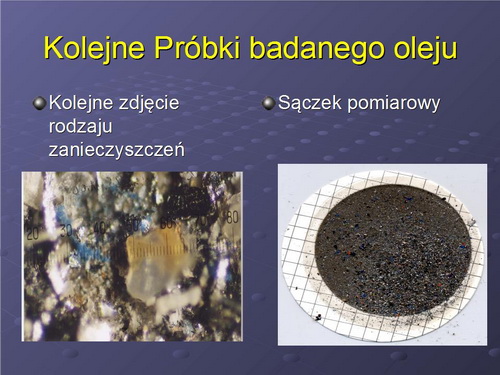

- microscope oil examinations

- this method allows us to define solid particles in the oil, with indication of their provenience and ISO 4406 cleanliness class

Example of microscope oil examination.

Specialised Oil Examinations

- Oil viscosity.

- Acidity number.

- Oil water content.

- Oil cleanliness class according to NAS and ISO 4406 (laser and microscope methods).

- Content of chemical elements in the oil.

- Wear-out material content

- Other

In case of cleanliness class examination by microscope method we define solid impurities content and we identify their origin.

We attach our commentaries and recommendations to the report, that will improve given device functioning.

Impurities kinds’ classification.

NEW

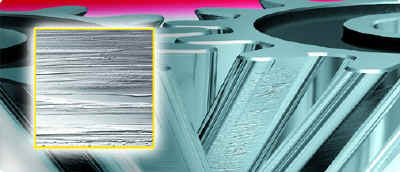

Revitalizants – new and non-invasive technique of machines and devices repair

Revitalisation is an advanced technique of care after mechanical devices such as motors, pumps, hydraulic sets, etc. by means of chemical means added to lubricants or oils. Revitalisant strengthens upper layer of metal and produces a reinforced carbide cover. This way it rebuilds the wear-out, giving the detail extraordinary hardness and smoothness.

At the moment revitalisation technology is used in many European countries, in Asia, Australia, in USA in all branches of industry, especially in motorisation, energy, shipbuilding and mining sectors. More and more frequently it is being used motors and gearboxes of ships, bearings of steam turbines, gas and wind turbines.

| Revitalisants improve work of: | |

|

|

ADVANTAGES:

- bringing back devices’ parameters up to near the initial level

- increase in lifetime or mileage of the device (1,5 up to 3 times)

- smoothing the cooperating parts, that makes them more resistant and protected

- fuel economy (in case of engines) up to teens percent

- 6% to 12 % of energy economy in devices

- lowering exhaust gases toxicity level

- improvement of the engines power up to 3%

- considerable noise reduction

- reduction in vibration level

- reduction of mechanisms breakage incidence

Before revitalisant use

After revitalisant use

KNOW US BETTER

If you want to get more information about possibility of revitalisation of your device, please fill the form and we will contact you back.

Usługi Serwisowe dla Turbin Gazowych

Usługi dla układów olejowych turbin gazowych:

- Wymiana olejów dla turbin gazowych

- Czyszczenie instalacji poprzez wysokociśnieniowe (50 MPa-100 MPa) hydrodynamiczne czyszczenie rurociągów. (Opcja w zależności od stanu zabrudzenia rurociągów).

- Płukanie układu olejowego na obejściach, do osiągnięcia zamierzonej klasy czystości rurociągów i oleju.

- Monitoring olejowy turbin w pełnym zakresie parametrów fizyko-chemicznych, dodatkowo przedstawianych w sposób graficzny, ze wskazaniem trendu zachodzących zmian.

- Usługi stało serwisowe dla układów olejowych turbin.